A microturbine is a small device used in a variety of devices. As the name implies, the microturbine, despite its small size, belongs to the turbine family and produces electricity. The shell of this microturbine, made by Petsako, is made of 310 steel material and can withstand temperatures up to about 1200 degrees Celsius.

The casting of this product has many complexities and difficulties due to the very sensitive groove in the inner body of the shell and it must have a good surface smoothness. The product has been in research and design for about a year, and was finally built after testing more than 10 alloy casting companies.

Due to its special difficulty for machining, the material used takes more work and requires more drills, because from time to time, the drills used in machining are damaged and crushed.

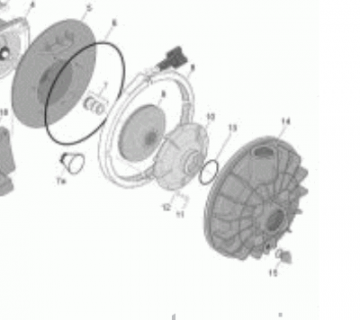

The general device in which this shell is used is also called a turbocharger, which is even used in some cars. So far, we have made 8 pieces of this device for one of our customers, and we have the possibility of making a general turbocharger for other customers in different sizes.

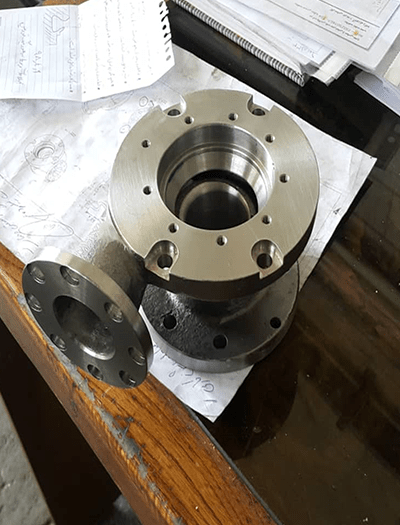

To make this shell (Turbine Housing) called Turbine Housing, we first designed the computer 3D model after receiving the construction plans from the main customer, and then we created the relevant casting model, the opposite of which You can see below.

After that, we started the casting operation, the pictures of which are given below.

And finally, we talked about machining and finishing the piece. As you can see in the main image. Although it took more than a year for Andy to make the piece, we weren’t upset, disappointed, or tired at all, and we tried to find the final solution. We are also ready to provide services for any other complex part for you and we will be by your side with honor and authority to achieve your desired products. Hoping for sustainable cooperation and further strengthening of the infrastructure of our dear country Iran.

English

English